How To Repair A Hole In A Fiberglass Boat

How To Repair a Fiberglass Boat

Few things are more disheartening to the gunkhole owner than staring at the fuzzy border of broken fiberglass. Nevertheless, the repairability of fiberglass is one of its best characteristics. The most horrifying pigsty in a fiberglass hull is quickly healed with a bit of glass fabric, a supply of resin, and equal parts skill and care. And the repair is less patch than graft — a new piece of skin indistinguishable from the old.

Fiberglass lay-upwards is nothing more than than layers of glass fabric saturated with polyester (or epoxy) resin, nonetheless most boatowners imagine a self-applied repair every bit merely slightly more than durable than a wet Band-Aid. This is a false concern. Follow a few elementary rules and your lay-up will exist just as durable equally the remainder of the gunkhole.

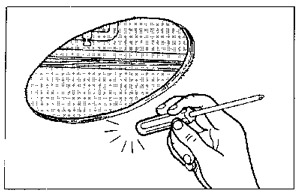

Cutting Abroad the Harm

Impact damage most ever results in some associated delamination. Tap the impact area with the cease of a plastic screwdriver handle to determine the extent of the damage; solid laminate sounds sharp, delamination dull. Check inside the boat to make certain zip is in the way, then make a circular or oval cut to remove the damaged area. Never endeavor to save damaged fiberglass; e'er cutting it out and replace it with new laminate. Bank check all the edges and enlarge the hole if you find any boosted delamination.

Working from Inside

If the impairment area is pocket-sized and above the waterline, make the repair from inside the hull, if possible. You lot are going to bevel the border of the hole with a 12-to-1 chamfer, so if yous repair a 3-inch diameter hole through a one/ii-inch-thick hull from the outside, you lot stop upward with virtually 15 inches (diameter) of surface damage to refinish. Repair it from the inside and you accept only a three-inch hole to refinish.

A 2nd reason to make the repair from the within is that you can back the hole on the outside with a polished surface, creating a mold that allows y'all to lay-up the repair the aforementioned way the gunkhole was built--gelcoat first. Very little end work volition be required.

Dewax

Before grinding, ever launder the area around the hole thoroughly with a dewaxing solvent. The original fiberglass volition have traces of mold release on the outer surface and wax surfactant on the inner surface. If you fail to remove the wax starting time, grinding will drag information technology into the lesser of the scratches and weaken the bond.

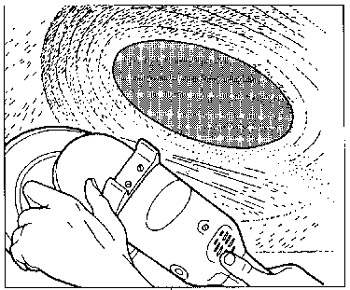

Grind

During the lay-upward process, because each layer is applied earlier the previous one fully cures, each application of resin links chemically with the previous one to form a solid construction--as though all the layers were saturated at once. Unfortunately, no affair how strong the laminate-to-laminate bail, the initial bond of any repair is mechanical, not chemical. Consequently, grinding is the key to getting a strong repair.

Apply a disk sander loaded with a 36-dust disk to grind a 12-to-1 bevel effectually the perimeter of the hole within. Also grind a rectangular area of the inner surface a few inches beyond the bevel to suit a finishing layer of material. Protect your eyes with goggles and your lungs with a good grit mask. Long sleeves will reduce skin irritation. Tilt the sander then that just 1 side of the disk is touching the surface and the dust is thrown away from you. Afterwards yous castor abroad the dust and wipe the area with an acetone-dampened rag, the sanded surface should have a uniform dull expect.

Mask and Mold

To prevent any resin runs from adhering, requite the outside surface of the skin around the pigsty a heavy glaze of paste wax, taking intendance not to get any on the border or inside the hole. Mask the area beneath the hole.

Cut a flake of shine plastic laminate (Formica) or sparse clear acrylic (Plexiglas) a foot larger than the hole. Wax this backer, and so spritz it with polyvinyl alcohol (PVA) mold release. Screw or tape the backer to the outer surface. If the hull is apartment or curving in only one management in the harm area, the backer will presume the correct bend. If the hull is spherical, i.e. curving in two directions, acrylic screwed to the hull can sometimes exist coaxed into the correct shape if warmed with a heat gun (before applying the mold release).

Fabric

Cutting sufficient fiberglass fabric to fit the pigsty. Unless you have reason to follow a dissimilar schedule, begin with two layers of 1 1/2-ounce mat, then alternating mat and 6-ounce cloth. The number of laminates will be determined by the thickness of the hull; you will roughly need one layer for every i/32 inch. Cut the first layer of mat the full size of the ground low, then cutting subsequent pieces about an inch smaller. This lodge of largest slice first, then progressively smaller pieces is how you are going to apply the new material. We do it this counterintuitive way, particularly with polyester resin, because information technology maximizes the expanse of the secondary bond, the adhesion of the new material to the onetime laminate.

Using Polyester or Vinylester Resin

For above-the-waterline repairs you can employ either polyester or vinylester resin. Of course, for an fifty-fifty stronger repair you tin can too use epoxy, but not if the surface of the repair will be gelcoat. (Yous should use epoxy for underwater repairs.)

If you are doing your repair with polyester or vinylester resin, you need laminating resin. Laminating resin does not fully cure while exposed to air, which allows yous to get a chemical bond between the multiple laminates you will be applying. To get the concluding laminate to cure, y'all merely seal it from the air, either with a plastic or by coating it with polyvinyl booze (PVA) mold release.

Catalyst

The catalyst for both polyester and vinylester resin is methyl ethyl ketone peroxide, or MEKP. Exercise not confuse MEKP with the common solvent MEK; they are not the aforementioned.

Polyester resin usually requires 1 to ii pct of hardener past volume (follow the manufacturer's instructions). Equally a rule of thumb, four drops of hardener will catalyze 1 ounce of resin at ane percentage. Exist sure to stir the catalyst in thoroughly or part of the resin will be undercured, weakening the lay-upwardly.

You can accommodate the cure time by adding more than or less catalyst. Temperature, conditions, and the thickness of the laminate all affect curing times. Some experimentation is generally required. The mix shouldn't kick (start to harden) in less than thirty minutes. Hardening in almost two hours is probably platonic, but overnight is merely as good unless the wait volition hold you up. Always err on the side of also footling goad; if you add too much, the resin will "cook," resulting in a weak lamination.

Gelcoat

Gelcoat is essentially pigmented polyester resin. Start the repair past spraying or brushing about 20 mils of colour-matched gelcoat onto the waxed backer. Check the gelcoat thickness with a toothpick; 1/32 is about 30 mils.

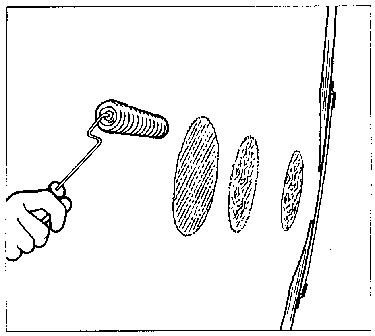

Lay-upwards

When the gelcoat kicks, wet it with polyester resin and lay-upward the first two layers of mat and one layer of fabric, compressing them against the gelcoat and working out all voids and bubbles with a resin roller and/or a squeegee.

Let the first three plies kick, and then lay up iv boosted plies. Never lay upwards more than than four plies at a fourth dimension or the generated estrus may "melt" the resin and weaken it. Go along the lay-up 4 plies at a time until the repair is flush with the interior surface.

Finish

For a finished look, cut a rectangular piece of mat and ane slightly larger of cloth and apply these over the patch, smoothing them with a squeegee. Seal this superlative layer with plastic or PVA to let a full cure.

Remove the backer from the exterior surface. Fill up imperfections in the new gelcoat with gelcoat paste and allow it to cure fully. Clean the area effectually the patch, then sand, if necessary, and polish the repair area.

Author

Don Casey

Contributor, BoatUS Magazine

Don Casey has been one of the most consulted experts on boat intendance and upgrades for 30 years, and is one of the BoatUS Magazine'south panel of experts. He and his wife cruise aboard their thirty-footer part of the year in the eastern Caribbean area. His books include Don Casey'due south Complete Illustrated Sailboat Maintenance Manual, and the recently updated This Old Boat, the bible for exercise-information technology-yourself boaters.

BoatUS Magazine Is A Benefit Of BoatUS Membership

Membership Benefits Include:

-

Subscription to the print version of BoatUS Magazine

-

4% back on purchases from West Marine stores or online at WestMarine.com

-

Discounts on fuel, transient slips, repairs and more at over 1,200 businesses

-

Deals on cruises, charters, automobile rentals, hotel stays and more than…

-

All for simply $25/year!

How To Repair A Hole In A Fiberglass Boat,

Source: https://www.boatus.com/expert-advice/expert-advice-archive/2012/july/how-to-repair-a-fiberglass-boat

Posted by: dickinsonlesse1952.blogspot.com

0 Response to "How To Repair A Hole In A Fiberglass Boat"

Post a Comment